During machining of non-ferrous materials and precious metals, limits of carbide quickly arise: wear, stability, finish.

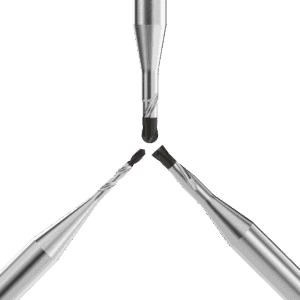

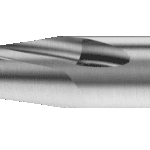

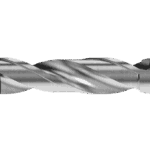

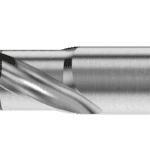

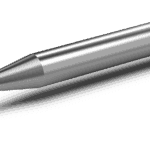

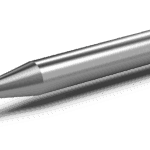

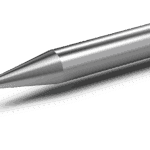

DIAFORCE was created to overcome these limitations, using PCD and specially designed helical geometries. Our helical end mills and twist drills, machined from solid PCD with latestgeneration lasers, combine hardness, dimensional consistency and superior surface quality.

We have optimized profiles, angles and sharpening for diameters from 0,1 to 3,0 mm, maintaining the tight tolerances typical of watchmaking and medical industries.

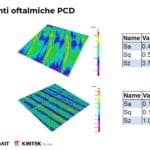

Each batch is checked using dedicated metrological instruments to ensure extended tool life and low roughness on aluminum, brass, copper, bronze, gold, silver, plastics and composite materials.

It is the result of a collaborative effort between design, production and quality control: advanced technologies, yes, but above all, people who pay attention to details.

With DIAFORCE, you equip your machine with a micro-tool designed to last, cut cleanly and repeat results.